Common Challenges In Metal Fabrication And How To Avoid Them

Metal fabrication involves several steps, from selecting materials to final assembly. Different factors can affect the quality and efficiency of the process, leading to delays or defects.

Identifying common challenges and finding ways to address them ensures better results. Experienced metal fabrication companies in Dubai follow strict measures to reduce errors and improve efficiency in every stage of production.

Material selection issues:

Choosing the right material is essential for durability and performance. Some metals may not be suitable for certain environments, leading to rust or structural weaknesses. To avoid this, it is best to consider factors such as strength, weight, and resistance to corrosion before selecting a metal. Consulting with experts ensures that the material meets the specific needs of the project.

Inaccurate measurements:

Precision is important in metal fabrication. Small errors in measurements can lead to parts that do not fit correctly, causing delays and additional costs. Using advanced measuring tools and digital design software helps maintain accuracy. Double-checking specifications before fabrication also reduces the chances of mistakes.

Welding defects:

Welding is a key step in joining metal components. Poor welding techniques can cause weak joints, cracks, or distortions in the final structure. To avoid such issues, skilled welders should follow correct procedures and use appropriate welding techniques for each material. Regular inspection of welded parts helps detect defects early.

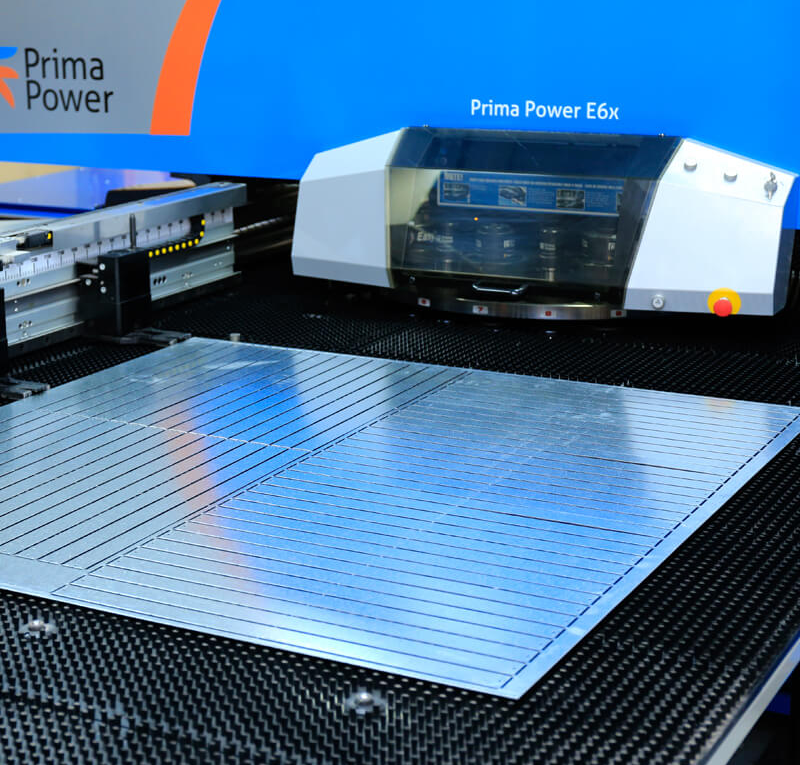

Equipment malfunctions:

Metal fabrication involves various machines and tools. If equipment is not maintained properly, it can lead to production delays and inconsistencies in quality. Regular servicing and inspection of machines prevent unexpected breakdowns. Using modern and well-maintained equipment also improves efficiency and accuracy in fabrication.

Surface finishing problems:

After fabrication, metal surfaces need proper finishing improving their appearance and durability. Common issues include rough edges, scratches, or uneven coatings. To avoid these problems, finishing techniques such as polishing, sandblasting, and coating should be done carefully. Selecting the right finishing method for each project improves the final look and protects the metal from damage.

Managing production timelines:

Delays in fabrication affect overall project completion. Poor planning, material shortages, or unexpected design changes can slow down production. To keep the process on track, detailed planning and coordination with suppliers and clients are necessary. Having backup materials and flexible scheduling also helps in handling unexpected delays.